I

wanted to have a couple of US Army truck, so I bought some Heller

kits.

The moulds are the same used by Airfix box, so discussing one is like

looking at the other one. Three olive green moulds, a transparent

set, a decal set and the instructions make up the kit.

Everything

looks well done, although a lot of ejector pin marks need to be removed

by filling or by sanding. The parts are quite well depicted, but I’d

have preferred to have some details as separate parts. The surfaces

have the Airfix old kits fashion, which I sentimentally like. The

plastic is quite soft to work with and reacts very well to liquid

glue, requiring a bit more attention with the brush.

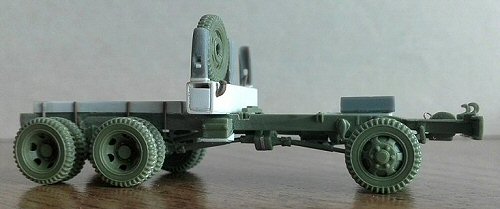

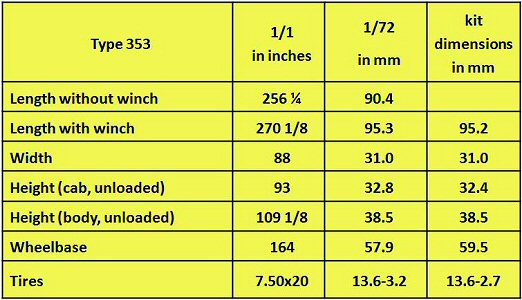

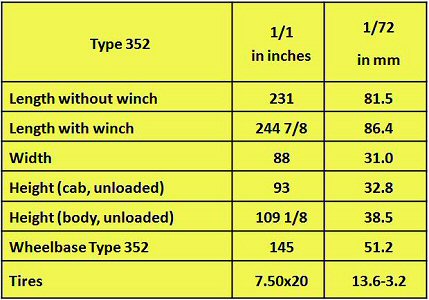

|

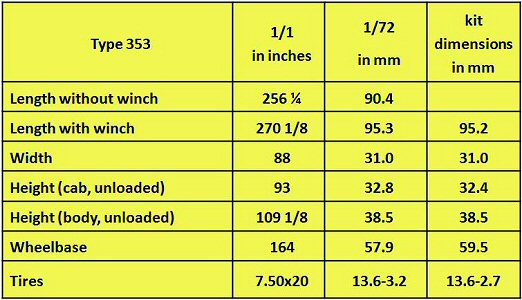

Dimensions

are quite correct,

only the wheelbase is about 1.5 mm too long. |

|

The variant proposed in this kit is the open cab truck with steel

body. The supply catalogue number for the truck 2 ½-ton, 6x6,

GMC CCKW was G508.

Two

types of chassis were used for the CCKW, the type 353 (used in this

kit), was the longer one. The shorter version, used for about the

10% of the CCKW production, was called type 352.

About the cab, the earlier production vehicles had the closed cabins

(1st, 2nd and the 3rd series). Starting from the 4th series, March

1943, the open cabin was adopted (there were also a 5th and a 6th

series).

The CCKW-353 proposed by the kit has the winch, used by both chassis

type (short and long) and on almost half of the production total.

The kit chassis has Timken split axle. It was also used the Chevrolet

banjo type, but the different axle type meant also a slightly different

layout of the drive shafts. You easily can get a range of different

variants with a little conversion work; the easiest could be swapping

the steel body to a wooden one taken from the Academy kit.

Good

info sources of information on the net can be found on dedicated sites

such as www.cckw.org or

www.gmccckw.nl , here

www.ww2cckw.org/jimmy_ancestry.htm,

you can find a very interesting article in ten parts and last but

not least, the technical manual TM 9-801 and TM 9-224 are full of

useful info too.

A very important thing when using photos of restored vehicles is to

remember that they could be subject to personal interpretation or

have a post war up grade (such as the shortened rod of the radiator

grill).

I made

the variant proposed by the kit, adding some improvements, as one

model and concerted a second one into a short wheelbase truck.

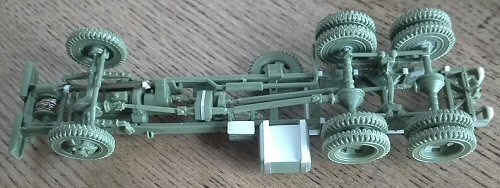

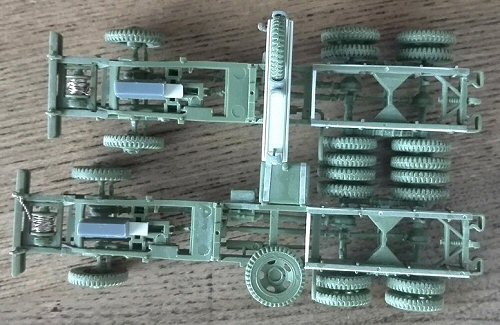

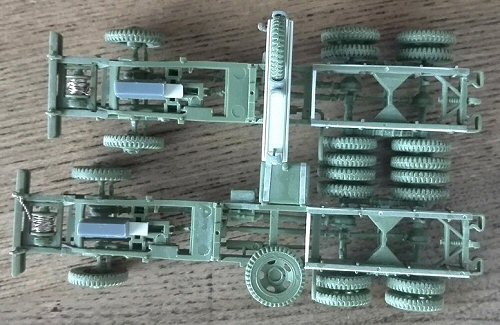

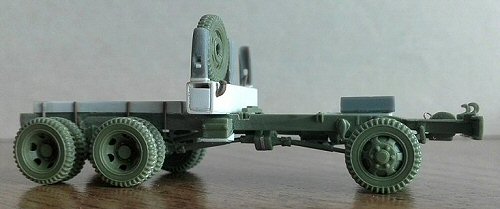

Chassis

|

- The

tank # 9 belly is open. I closed it with thin plastic sheet. The

metal belts of the tank were removed and replaced by thin metal

stripes while the tank supports were made by plastic rod which endings

were filed to depict its “U” section.

- A

metal wire was wrapped around the empty winch.

- Also

the battery box # 8 belly is open, after having closed in the same

way. I added its housing by thin plastic sheet.

- The

towing hook is shown up side down in the instructions.

- The

winch power shaft is missing. I made it by stretched sprue and little

plastic triangles for the gimbals.

- A

careful job was needed to obtain the proper placement of the drive

shafts, correct for the split type axle.

|

|

- To

avoid open spaces between the chassis and the bonnet, I shimmed

the engine top using plastic pieces.

- The

spare wheel has five holes. While this error on the front wheels

were been corrected by the mould maker, the spare wheel was forgotten.

Luckily, it's partially hidden and so I ignored it too.

|

|

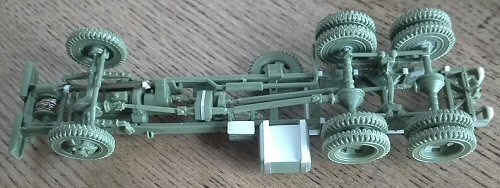

- The

7.50x 20 wheels in my kit are correct (all have six holes), the

diameter is depicted correctly but they are slightly thin. I kept

them as they are: the correction is almost impossible and I didn’t

want to look for a replacement (Armory has a resin set).

- The

chassis frame height was the same along all its length; the higher

section where the bed lies wasn’t solid, but formed by a second

frame fixed to the chassis. To depict this difference I glued two

very thin plastic stripes. Another stripe was used to close the

frame front. I also made the thin rods which kept these frame in

place using some stretched sprue and little plastic pieces.

|

|

- I

increased the rear bumpers lower edge by plastic shaped in place

and I thinned its thickness from inside.

|

|

|

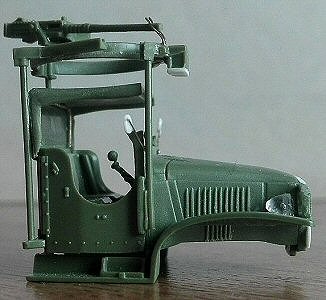

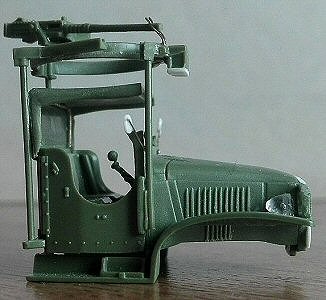

Cabin

When

assembling the cabin, I didn't follow the instructions, attaching

it to the engine hood as a sub assembly. This made the painting job

a lot easier, but that's personal.

|

- The

brush guards are very thick and hide the lights. I removed the inner

rods (very thin on the vehicle) while the shaped edge, which forms

the outer frame, was thinned carefully. The new rods were made with

stretched sprue. There should be two horizontal rods, but I felt

the lights obscuring effect was too much so I added only one.

- The

lights are moulded in transparent plastic. I glued them in place;

they will be painted together with the cab.

- The

bonnet upper cover is a millimetre too short: it should cover the

grille thickness. I added plastic shaped in place, paying attention

to obtain the correct shape.

- The

mirror supports are much too thick and the mirrors small. I replaced

both by metal wire and plastic sheet.

|

|

- I

reduced the oversized windshield hinges, while the dash board front

recesses were filled and flattened.

- The

rectangular holder for the support # 39 on the cab right side was

resized.

- To

give the steering wheel the correct alignment a little adjustment

of its interlock was needed.

- The

edges of the fabric cabin hood where thinned. I added the frame

which keeps the fabric in shape by metal wire. It was glued on using

the dry fitted windshield for a correct placement.

- The

technical manual shows the correct way to store it, rolled under

the windshield when that was folded down to prevent the glass breaking.

The windshield could also be opened up. In this case the external

frame remained vertical and only the interior frame folded up.

• Under the fenders, behind the wheels, there was another

louvre on each side; I made their vents with thin stretched sprue

segments.

|

|

- Since

the seats were moulded solid to the cabin, the floor bottom has

a large hole which is their inner side. I closed the floor with

a plastic piece to restore the floor.

- The

grille has 9 thick rods (they should be 14) with the bridge class

plate moulded on. I removed the bridge class plate, which was replaced

by thin plastic sheet.

- The

kit also has a driver. The arms are separate, which is good, but

the soldier is undersized. You wouldn't see him in a closed cab

truck, but although this one is the open version, I'd choose to

send him to the spare part box.

|

|

Flat

bed

- The

toolbox floor was added by plastic sheet.

- I

added the inclined benches position supports, made in stretched

sprue.

- The

opening on the right side, above the fuel tank cap, was missing.

Using a file, I made a small notch.

|

|

M36

mount

The standard

AA MG mount for the open cab was the M36 type (however exceptional

use of the M37 is photographically documented), but it wasn’t

always present. Although shown as optional in the tarpaulin instructions,

it could be used with or without the fabric hood depending on the

effect wished by the modeller.

There

were two M36 mount variants, which differed in the horizontal arms.

The kit depicts the type with the “U” section straight

arms. The other type had “C” section triangular arms. |

- Compared

with the usual WW2 photos, the vertical supports look short: the

ring height can be adapted using a row of holes placed at regular

distances along the vertical rods. Since these rods also look much

too thick, I replaced them by stretched sprue.

- The

position suggested for the right supports are much too far from

the cab so I modified their position to get them closer. After having

repositioned the vertical supports, the interlocks references in

the horizontal arms were changed. I carefully cut off the rear arms

and, after having cleaned these and the ring, glued everything in

the correct place using the vertical supports as dry fitting references.

|

|

- The

48 inches ring section is much too thick. I kept the exterior diameter

and I thinned it from inside.

- The

MG fork is turned to point inside the ring. If you wish to point

the MG outwards, the fork must be cut from the sliding base and

glued inside out. I kept mine as it is to get the travelling position

(gluing the .50 in the correct position) adding its thin travel

locks made by thin metal wire.

|

|

|

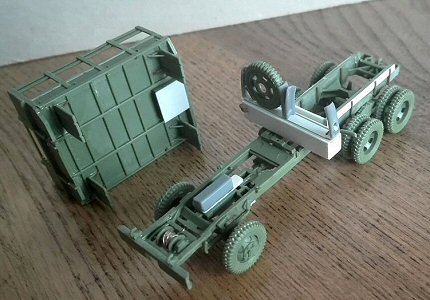

CCKW-352

Conversions

The

easiest way to convert a 353 variant is getting rid of the winch.

The front bumper can be scratchbuilt or taken from the Academy kit.

Another possible conversion way is swapping the steel body with an

Academy wooden body because this type was used as well. The use of

the Hasegawa tanker truck body or dump truck body is possible but

more complicated.

I preferred

the less complex conversion ("really simple" would be more

correct) to a short wheelbase CCKW-352, by modifying the chassis and

the flatbed body. I didn’t correct the 1.5 mm difference in

the wheelbase because the kit is shaped around this difference and

I though correcting it could give major problems.

|

_____________ _____________ |

The

chassis

- I

shortened the chassis cutting it twice. The first cut just in front

of the raised section, filing backward to have a larger gluing surface,

shortening the overall length of 6.7 mm which is the wheelbase difference.

The chassis length difference is 8.8 mm and I made the second cut

forward of the rear bumper.

- The

shelf for the spare wheel was removed; on the opposite side I filed

the tank interlock.

- Above

the tank, I made the spare wheel housings by shaping four sprue

segments. The two external ones had also a squared hole in which

the travel locks went, made by stretched sprue and plastic sheet

chips. Having only one spare wheel I left the second housing empty.

|

|

___________________ ___________________ |

- The

fuel tank was inside the transversal housing placed between the

cab and the body. This adaptation and the one below are the "hardest"

part of the conversion. Using a drawing to scale down the dimensions,

I started filing a thick sprue section to obtain a squared section.

Around this I glued plastic stripes to make the housing, leaving

a 0.5 mm space between the top of the tank and the top of the housing.

To this I added the curved filling pipe and its cap made by stretched

sprue.

|

|

- The

drive shafts and the exhaust piping were shortened accordingly.

|

|

The

body

- The

CCKW 352 body was 39” shorter. I shortened the bed cutting

10.5 mm from the front and 2.5 mm from the rear.

- The

sides were shortened to 38 mm cutting them in five pieces, which

are the four panels with a rib (9.3 mm long) and a single rib. I

glued everything together on a glass plate to get a perfect flat

construction.

|

|

- Next

the benches were consequently shortened. The ribs placed on the

bottom were cut off and placed using the side ribs as references.

|

|

_______ _______ |

Decals

I didn’t

find a single photo of the only truck offered in the decal set:

-

W-4491967-S, a truck of the 1st Army 3549th Transportation Corps.

Basing on the photos I’ve seen, I think the War Department

letter “W” was already discontinued at the time the

number 4491976 was allocated. Currently this registration number

is written on the bonnet of a restored CCKW 353 without winch, but

I don’t know if it is its original number or it is applied

fictionally.

|

Conclusions

There

is little choice for an open cab, but luckily nowadays this is a quite

good kit (earlier production kits had the wrong forward wheels shown

in the Stephen Brezinski

review). In this kit I think nothing is really wrong or irreparable

despite some details seriously need a bit of TLC, which could came

from an aftermarket set. A better brush guards is strongly wished.

With some work this kit can give us a good replica and with a bit

more work it can be converted in different variants.

I

think some items for the load or a crew to fill the body would be

a welcome improvement as well as a couple of options in a new decal

set.

Preview

sample purchased by the author.

This

model can be purchased from

|

________________

________________