The M4 tank was produced by five plants: American Locomotive Company (ALCO), Pressed Steel Car (PSC), Baldwin Locomotive Works, Pullman Standard, (each of these producing its own M4, with some little peculiar features) and Chrysler (producing the more different composite hull before and the 47° hull after).

Actually the 1/72 M4 kits on the market depicts the ones produced

by the ALCO plant (Dragon and Trumpeter) while other gives mixed features.

After having made some M4 Sherman’s, I find myself considering

the unsatisfying fact that a Baldwin model is actually still absent.

Since I had a lot of spare parts resting in a box and an Italeri fast

assembly Sherman III/M4A2 kit (that I bought as B-plan for my Trumpeter

M4 upper hull correction), I thought to try out an experiment: make

myself a M4 Baldwin. |

|

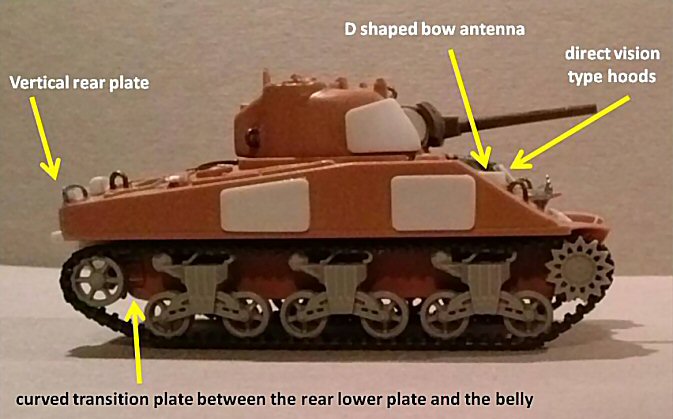

The differences From the 1/72 modeler point of view, the Baldwin M4 differs from the ALCO/Pullman ones in four points :

1. the hoods are always the direct vision type;

In other aspects, the Baldwin tanks followed the same evolution of the other production lines. So you can find the following combinations:

1. bolted transmission cover and pistol port turret with M34 mount; |

|

The conversion job Cheap and well done (although simplified), my Italeri M4A2 was converted to the M4 standard using spare parts and scratch building; this job is not described here, being irrelevant for the purposes of this article. The following specific works described are useful on every kit chosen.

|

|

|

|

|

|

|

|

| That’s all! This conversion is easy and the real needed piece is the direct vision hoods part, the rest can be scratchbuilt. The job can be made with any kit you prefer, giving us the opportunity to expand the modelling potential of this tank. The Baldwin plant produced 24 percent of all welded 56° hull M4 tanks, making this quite a common type, that can be found on many photos taken on the Mediterranean fronts and in North West Europe. |

|